COMPANY ADVANTAGE

1. Hardware Advantage

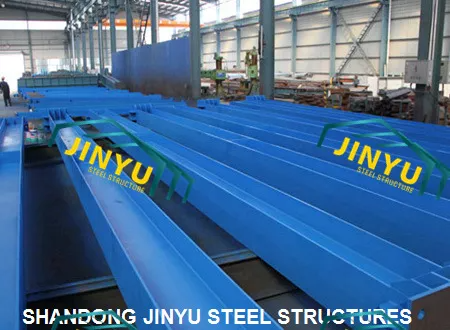

We are one of the top 3 steel structure manufacturer in northern China, with 260, 000 SQM production area of 7 workshops, and 4 sub-factory of 835,751 SQM factory total area, our annual capability reaches 250,000 tons.

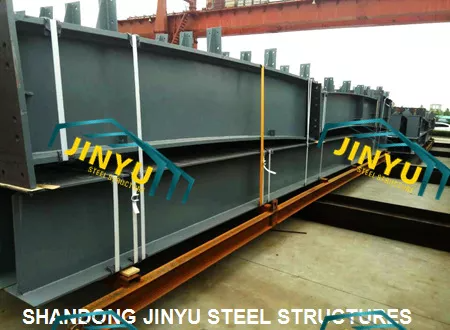

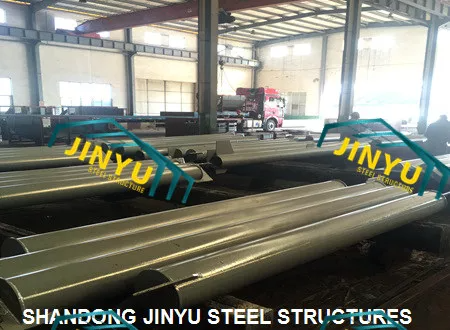

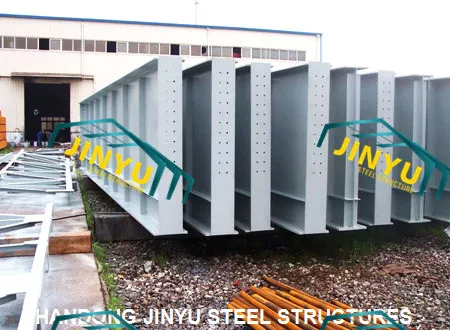

We have Box column production line, H-beam of thick edge production line, Corrugated web beam production line, building envelope production line, 360-degree occlusal plate production line and other kinds of production line, major equipment are imported abroad. Powerful production capacity can completely meet the processing demand of different customers with high quality.

2. Soft Power

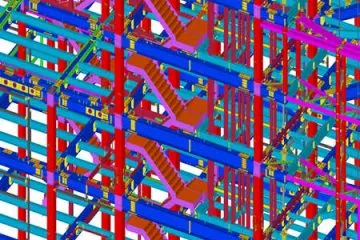

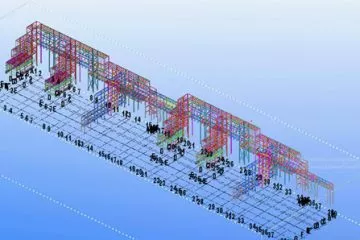

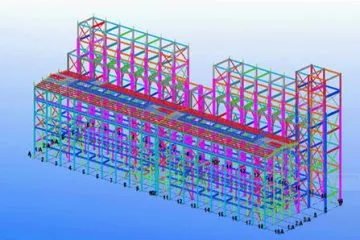

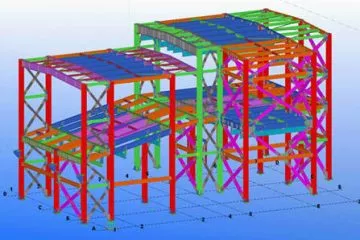

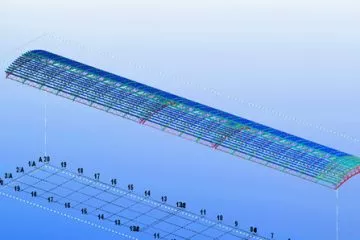

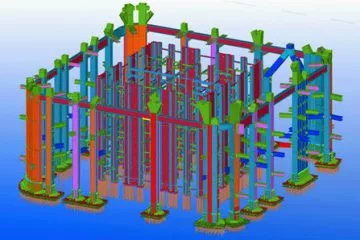

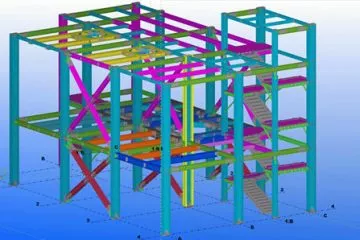

We own 16 TEKLA professional designers, by applying computer work station, they make the model for steel structure items assembling, define the assembly dimension and inspect the connection status of each joint in three-dimensional way through difference perspectives, which has optimized the design for realizing 100% successful bolt installation, greatly enhancing working efficiency.

We own 15 professional STAAD-Pro designers. As for secondary design and partition treatment of drawings, our design team applies STAAD-Pro together with Ram Connection module to optimize joint design to establish scientific and reasonable assembly design scheme.

Design Software: We use a series of advanced computation, analysis, design software, and dwgs detailing& mapping software, it including American SAP2000, American STAAD-Pro connection calculation software, Korean Midas gen software of finite element analysis, PKPM, 3D3S, Finland Xsteel, and AUTOCAD, etc.

We use computer workstation to Build 3D model, optimize the design scheme, which increase the product accuracy and material use ratio effectively.

Design Capabilities: High-rise & skyscraper steel structure design, the elastoplasticity time-history analysis, pushover analysis, complex space structure design, ultimate bearing capacity analysis, elastoplasticity yield analysis and other computation analysis capabilities.

Welding Technology Research Institute: Corporation consists of a research office and a welder training center. As the specialized division for the research of pioneering technologies regarding various types of metal welding, the office is capable of assessing new building materials welding arts and the scientific and research projects of welding. The Welder Training Center is eligible for issuing the qualification certificate of construction welding technology test. The trainers in the Center have diverse certificates including the trainer certificate issued by the state employment training technical instruction center and the senior technician certificate of electric welding. The Center takes charge of technical training and welding examination certificate issuance regarding the manual electric arc welding, submerged arc welding, gas shielded arc welding and other projects.

R&D Cooperation: We have established sound cooperative relations with many high educational institutions, including Tsinghua University, Zhejiang University, Harbin Institute of Technology and Xi’an University of Architecture and Technology. Every year, different kinds of events and academic exchanges are held with the assistance of universities, industrial associations, academies of design and research and so on.

soft power

soft power

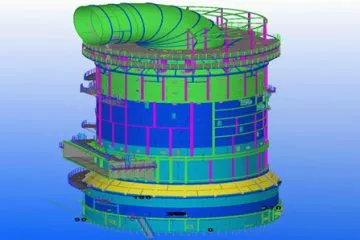

Huadian Power Plant Absorption Tower

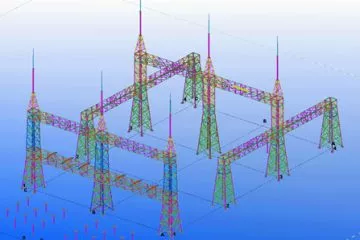

Iraq Booster Station

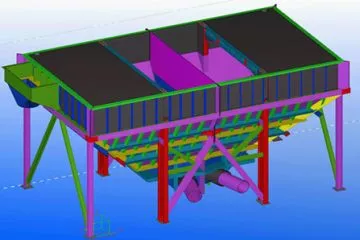

Argentina Steel Coal Hopper (one hopper has 4 opening, the opening is eccentric)

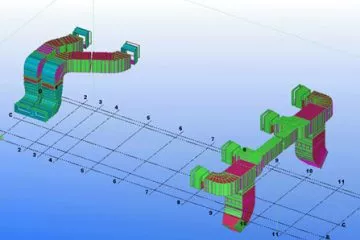

Saudi Arabia Gas Fired Power Station Comprehensive Pipe Support

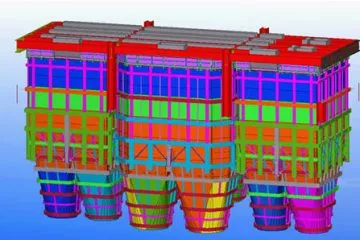

Turbine Building Of 10,000t India Power Station

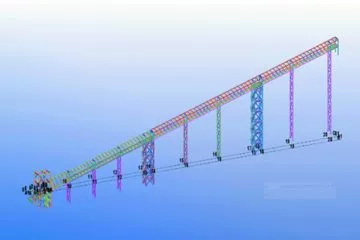

Iran 6# Coal Belt Conveyor Gallery

3# Transfer Station Of 6,000t India 4*300mw Coal-Firing Power Station

Roof Truss Of Binzhou Project

Yunnan Office Building 5600ton, (25M underground, 354M overground)

Zambia Mining Machinery

Samsung Mobile Phone Factory, 7400tons

Steam Generating Station, Vietnam

3. Quality Control

Scope of Testing: the Corporation is eligible to conduct comprehensive test over a series of products regarding the purchase of raw materials, the processing and production and the construction and erection in the steel structure industry. The testing capacity involves the national standards of China, Japan, Europe and the USA.

ERP System and Whole Production Route Traceability System

We have ordered the production ERP system as per its own characteristic, to realize the principle of each component only has one marking.

We realizes Raw Material Traceability System by sticking bar code on raw materials, semi-finished products, finished products and products ready for delivery, establishing systematic database procedures and scanning bar code database through code scanner.

Since the raw material passed the entry inspection and entered the plant, from cutting to painting and then to packing& delivery, the bar code will be transferred and pasted for four times for each part.

Non-destructive Flaw Detector

Raw Material Bar Code Retrospection

Half Product Bar Code Retrospection

Finished Product Bar Code Retrospection